How To Install A Vinyl Shower Pan

Although showers laden with ceramic tile look cracking, leaks are an inevitable fact of life. Yous can't presume your shower flooring is waterproof merely considering y'all see no visible signs of tile or grout harm. Ceramic tile showers are not waterproof; they are water-repellent. Under the tiled floor surface lies near 2 inches of cement mortar. When using the shower, this mortar becomes saturated with water. Small "cry holes" at the base of the drain fixture allow the water to move downwardly the bleed pipe. Still, over fourth dimension the water infiltration can cause harm to the grout, causing loose tiles and aging grout lines. Shower liners below the mortar are what protect the subfloor from deteriorating in the same way.

Most modern shower floors contain a flexible liner as a waterproof membrane beneath the tile and mortar. These liners are made of polyvinyl chloride (PVC) or chlorinated polyethylene (CPE). The membranes are used in lieu of the outdated lead shower pans that were used years ago (and would ultimately neglect over time). The flexible liners, available at plumbing wholesale stores and ceramic tile shops, are made of a rubber-like material that is impervious to water and resistant to the many chemicals found in a home. In fact, the stuff is probably an environmentalist's nightmare—it never seems to deteriorate.

The flexible liners conform to the diverse contours of the wood framing, bending upward at the walls and folding into corners. PVC liners tend to be stiffer and more than difficult to work with than CPE liners, so a CPE liner might be a smart way to go for whatsoever first-fourth dimension DIY'ers tackling the task. The drawback to CPE is that the material can be nearly three times as expensive per square foot as the PVC production.

Line information technology Yourself

Installing a flexible shower pan liner is not beyond the power of a smart exercise-it-yourselfer, only there are a few guidelines to help ease the process. This article volition assume the subfloor of the shower is constructed of plywood, although the same principles utilise to concrete flooring where the sloped mortar bed is applied below the pan liner. The installation method is the same for CPE and PVC liners, with the exception of the bonding agglutinative used for seaming.

For a typical plywood subfloor, begin by cutting a hole in the center of the shower floor for the drain assembly. First with a small pigsty; yous tin can always cutting away more material with a utility knife, merely you don't want the drain hole to be likewise big. Then lay the bleed base in the opening. Make sure the liner doesn't interfere with the drain's weep holes. Once you have made a skillful fit, apply agglutinative silicone caulk on both sides of the liner where it contacts the bleed. Plastic plumbing drains usually take a one/viii-inch flange lip that project'due south above the subfloor. In some cases this may cease some of the water from hands flowing into the drain. 1 solution to this is to route a aqueduct that allows the peak of the bleed flange to exist flush with the subfloor. Then solvent-weld the drain base of operations to the drain pipe using the advisable solvent cement.

To preclude the small-scale weep holes in the drain from getting clogged with cement or droppings, place washed pea gravel over the holes. It may help to comprehend the drain base opening with duct tape to keep out debris until you're ready to add the finished drain.

Many tile shower drains accept threaded, adjustable finished drains that permit y'all to arrange them to a wide range of finished floor thicknesses. The flexible liners attach to the drain similar a safety washer pinched between a nut and commodities. In one case the adjustable finished drain is tightened, all the water in the shower will menstruum toward the drain.

The pre-measured liner needs to lap upward the sides of the shower walls at least 9 inches. It is nailed to the framing studs of the shower most the top of the lapped edge. If it is necessary to seam together two pieces of material, a special solvent can exist used to glue them together to grade a single waterproof liner.

Spread the liner material from the drain body outward, toward the side framing and the curb so it lays flat on the floor. Fold the corners and boom or staple the liner to the sidewall framing or wall studs. Fasten 1/2 inch beneath the upper edge of the fabric. Piece of work your fashion around the perimeter of the liner, fastening it into the framing. Lap the border of the liner completely over the shower adjourn and boom it to the outside edge of the curb.

Tip: Are you likewise building the framing of the shower? If you can suit the crude framing slightly, installing the liner tin can be a much easier job. When framing a shower, leave i/4 inch of additional space at the finish of each corner. This means the total wall length is 1/2 inch shorter than the opening. The gap provides a proficient place to store the extra CPE membrane cloth that bunches up equally you round the corner. If you don't have the option of adjusting the framing, then just keep the corner folds equally flat and tight as possible.

Test the installation past plugging the bleed pipe and filling the shower basin with water just below the elevation of the curb, and then permit information technology sit for 4 hours. Check for leaks and repair as necessary. Retest the liner until you're sure the installation is leak-free. Completely bleed the h2o and dry out the shower before moving on with construction.

Above the Liner – Composite Marble Pan

I popular alternative to a tiled shower floor is a composite — or 'solid surface' — shower pan. Whereas the walls tin can still be tiled, this single-piece composite material will last nearly forever without any problems of water penetration. Virtually all new tiled shower installations develop cracks in sure grout joints inside the first v years. However, using a composite pan eliminates the grout joints in the floor and, in turn, eliminates the leaks. All you lot'll have to worry about is the grout joints at the wall/flooring transition.

The blended pan shown in the photos is considerably more expensive than a tile floor, but it is easier to install and will ensure you don't have to re-tile the floor as long as yous ain the home. These pans are custom made, poured into a form according to the exact measurements you provide to the supplier, so make sure the dimensions you specify are correct for your shower framing. The molded piece of composite as well features a pre-sloped surface to send water straight to the drain.

This unmarried-slice flooring rests on a bed of sand that conforms to the shape of the lesser side of the flooring and provides an adaptable, cushioning barrier between the floor and the liner. Make sure sand does non get into the drain and clog the weep holes. Spread the sand evenly over the liner surface.

Next, place the pan on the sand. Employ a carpenter's level to make sure the floor is level. Use a dowel or paint stick to adjust the bed of sand and then the floor sits level. Exercise your best to ensure the bed of sand has fifty-fifty contact with the underside of the composite floor. You'll need help placing the pan because the composite material is very heavy.

With the pan in identify and level, install the cement lath walls to the side framing. In this example, the bottom of the cement board should rest snugly on top of the blended floor, pinching information technology in place. So finish the walls with thinset and tiles, grouting the joints between the walls and the floor.

Where Can Yous Find a Shower Floor Like the I Shown Above? Nosotros at EHT become this question all the fourth dimension. You should expect up "Marble-Cultured" in your Yellow Pages, as most of these companies operate at a local level. Await for a visitor that offers "customized cultured marble products."

Above the Liner – Tile Floors

For the more traditional tiled shower floors, installation differs. Since you're not using a pan with a prefabricated slope, you have to create the slope. The slope in the floor allows all the wet to drain, eliminating the crusade of fungus, mold and odor. Plumbing codes crave a gradient of i/4 inch per foot, and the Tile Quango of America & ANSI standards recommend using "slope nether waterproofing membrane."

There are three primary ways to create the slope. The flooring framing tin can be pitched to grade the slope. You tin can besides use a special manufactured product that creates the required slope for yous (see Side Note below). Or, yous can lay a bed of latex-modified mortar and trowel the gradient onto the surface.

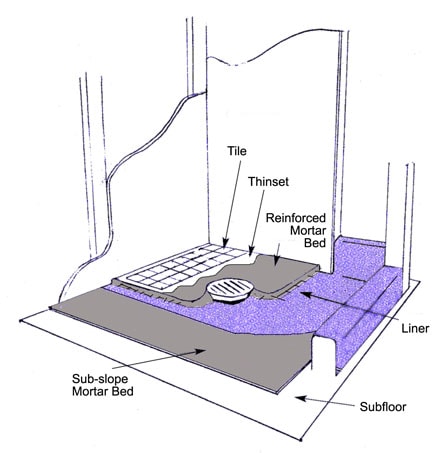

Afterwards the mortar bed has fully cured (or the gradient is otherwise created), so install the liner over the sub-slope, in the fashion shown above. So install a second mortar bed, reinforced with wire mesh and floated to the floor's concluding slope. Afterwards the second mortar bed has hardened, utilize the tiles with thinset. Make sure the thinset is shine with no hills or bumps to continue the tile flooring even and beautiful. Let the thinset to cure at least 24 hours before grouting.

Note: Earlier installing the shower floor, install the waterproof wallboard, positioning the bottom border of the panels 1/4 inch above what will be the finished meridian of the tile flooring to allow room for a control joint, later to be filled with backer rod and sealant. And when installing the wall panels, don't smash through the cement lath and pierce the liner where it laps up the wall framing; place fasteners to a higher place the liner instead.

Extra Project Tip from reader P.W. Ferraro :

Specially if you intend to install tile in the shower, yous should install black craft paper behind the cement board to prevent the studs from rotting out. The cement board won't rot when it gets wet, just it is not h2o-tight and the spacing on the cement lath fasteners is 6 to 8 inches. I besides suggest using dry out-pack grout rather than sand to foreclose the sand from going down the sub bleed.

Editor's Note: Thank you to Jeff Davis of Jeff Davis Structure (205-966-4813) and William Moulton of Better Built Construction (205-612-0508) for assistance with this story.

Source: https://extremehowto.com/installing-a-shower-pan-liner/

Posted by: donahuewholoney.blogspot.com

0 Response to "How To Install A Vinyl Shower Pan"

Post a Comment